Fatigue Assessment Using Body Joint Angles

Authors

Armin Bonakdar, Karla Beltran Martinez, Ali Golabchi, Hossein Rouhani, Mahdi Tavakoli

Abstract

Predicting fatigue in material handling tasks is crucial to prevent work-related injuries and enhance worker safety [1]. Fatigue affects movement coordination, which can be identified using inertial measurement units (IMUs) found in smart devices [2]. This study utilizes machine learning approaches to detect muscle fatigue by analyzing IMU recordings.

Methods

A study was conducted with seven able-bodied male participants (age: 24 ± 2). 9 IMUs (MTws, XSENS Technologies, NL) were used to calculate right knee, elbow, trunk, shoulder, and neck angles during a repetitive material handling task that included lifting a 16 lbs. box between two tables of different heights until the participant declares the Borg Rating of Perceived Exertion (RPE) scale of 9 out 10. Extracted features included the maximum, minimum, and average joint angles per repetition. Initial repetitions were used as no-fatigue references, while a portion of the end cycles represented the fatigue state. The aforementioned features and their associated labels were employed in various machine learning algorithms (ML), such as Support Vector Machine (SVM), K-Nearest Neighbors (KNN), Random Forest Classifier (RFC), Deep Feedforward Neural Network (DFNN), and Tabular Learning (TabNet). The objective was to evaluate the robustness of the extracted IMU-recorded features in fatigue detection. Furthermore, the RFC algorithm was utilized to determine the features’ importance and compare their impact on fatigue detection.

Results and Conclusion

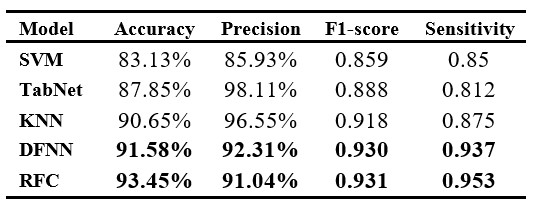

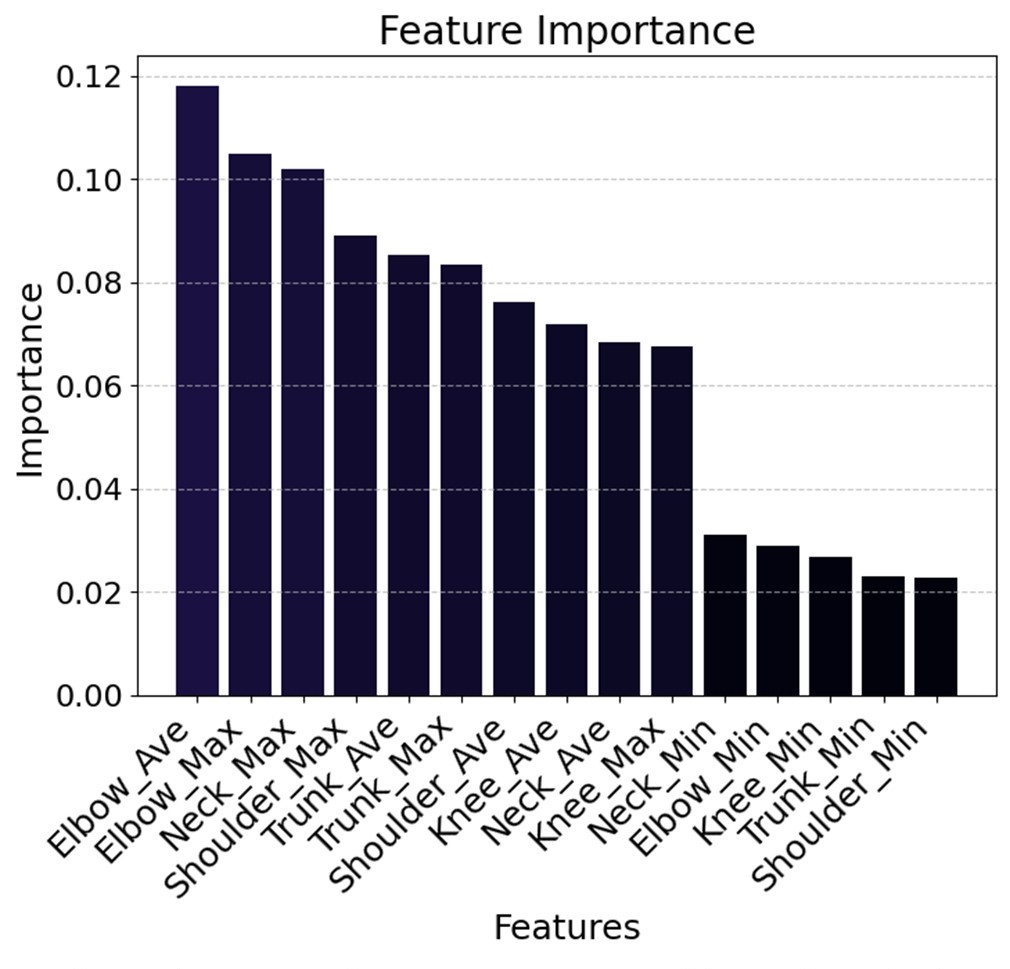

IMUs' extracted features were highly effective for fatigue detection, with RFC achieving 93.45% predictive accuracy and DFNN closely following at 91.58% (Table 1). In addition, the RFC findings indicate that average and maximum angles hold greater significance in fatigue detection compared to the minimum angle (Figure 1). This study highlights that IMU-recorded features such as maximum, minimum, and average angles from joint angles were efficient for fatigue prediction during manual handling tasks. The accuracy of the results suggests that IMUs can be used for fatigue detection in a workplace setting.

References

[1] Baghdadi, A., Megahed, F.M., Esfahani, E.T. and Cavuoto, L.A., 2018. A machine learning approach to detect changes in gait parameters following a fatiguing occupational task. Ergonomics, 61(8), pp.1116-1129.

[2] Jiang, Y., Hernandez, V., Venture, G., Kulić, D. and K. Chen, B., 2021. A data-driven approach to predict fatigue in exercise based on motion data from wearable sensors or force plate. Sensors, 21(4), p.1499.